Port Explores Industrial Symbiosis for Sustainable Growth and Environmental Resilience

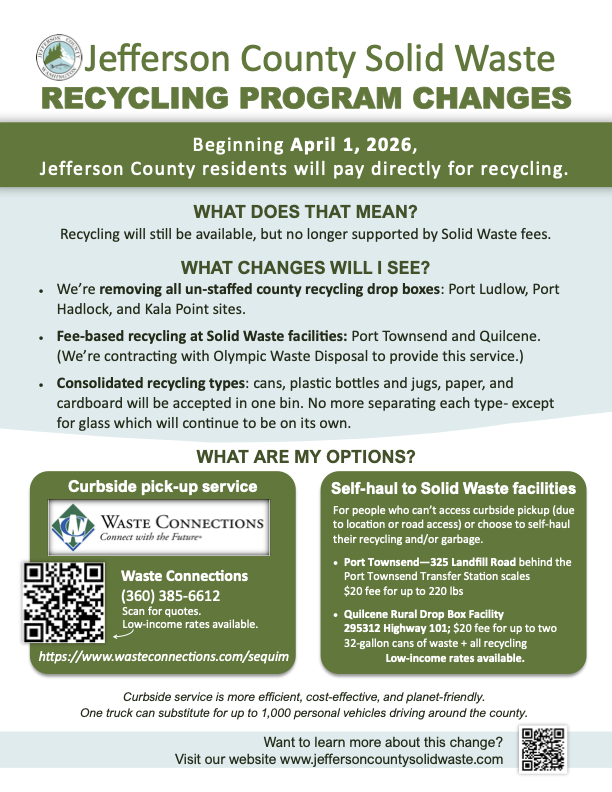

[caption id align="alignnone" width="2000"]

Port Executive Director Eron Burg at a Danish industrial park with a significant microgrid which includes energy created from solar, wind, hydrogen and biogas. Photo courtesy of Eron Berg [/caption]

News by Angela Downs

The massive federal funding cuts have spurred many to consider a pivot towards local systems of interconnectivity.

The Port’s Executive Director, Eron Berg, recently returned from a Sustainable Industrial Park tour in Denmark. The tour was funded by the Scan Design Foundation, with legislators' costs covered, while the Port covered Port representatives costs.

“I was pretty worried leading up to it about whether it would be worth my time and the Port's investment, and I would say absolutely, I would be eager to go again,” Berg said. “What I would do differently next time is I would want to have somebody from the PUD, the City, and the County, the Paper Mill and maybe the Foundry. I'd want a group of Jefferson County folks there together.”

Berg learned about and witnessed working resource sharing models producing energy as part of a microgrid. When considering our particular set of geographic logistics in an emergency, you can see how we are lacking in food, self-generated energy, and even water. We are vulnerable here, and our supply chain is fragile.

Berg sees these industrial symbiosis grids as a way to, at least in the worst case, have some publicly accessible phone charging stations that could get you onto a cell tower still working to communicate with loved ones. Outside of emergency response and crisis readiness, Berg sees potential for systems collaboration, such as using heat from the sewer system to heat the local pool.

He hopes that people will begin imagining for themselves the possibilities of interconnective industrial symbiosis. But from the Port’s standpoint, as a landowner that creates space for entrepreneurs and business people to show up and create jobs, there has to be the environmental benefit, cost-saving benefit, and waste revalue, all working together.

“It's our job to encourage businesses to really make money by engaging in these industrial symbiosis opportunities that also happen to be good for the environment. I think that was an important observation; these projects all have a business case behind them,” Berg said.

“I am worried that our current economic conditions are outstripping the ability for the jobs to keep up with our own marketplace, and it is really hard to imagine a Port Townsend that’s missing its tradespeople. It feels like it loses an entire dimension of its culture”

— Eron Berg, Port Executive Director

Many of the industrial examples on the tour were of garbage incinerators, and the heat generated was used to power district heating and utilities. They recycle everything from plastic to textiles and carpet. Culturally, they’re comfortable with the idea that the public will take the time to separate out the different materials so they can be reused and given new value.

This radical relationship to waste can take years of cultural reprogramming and requires alignment in legislature and shared goals.

Skagit County operated a mass-burn municipal waste incinerator, known as the Skagit County Resource Recovery Facility (SCRRF), from mid-1988 until May 1994. The incinerator was shut down in May 1994 by the Supreme Court ruling that classified incinerator ash as hazardous waste. The cost of disposing of the ash rose from about $50 per ton to $350-$400 per ton, and continued operation became uneconomical.

Copenhagen, on the other hand, has CopenHill, a waste-to-energy plant that is also an architectural landmark, featuring recreational amenities such as a ski slope, hiking trails, and a climbing wall. Designed by Danish architecture firm BIG, the plant burns waste to produce clean energy for 160,000 households while also serving as a public space.

They have developed a process that extracts and recycles 10-15 kg of metal for every 200 kg of slag (ash mixture). What is left can be used for fill for building and construction projects. The fly ash is collected from filters and used as a substitute for lime to neutralise residues from other industries.

Getting everyone at the table is a hurdle, but then providing education about systems science, developing communication and shared language, and building trust can take a long time.

Yet examples of working people taking initiative can be seen at the Jefferson Timber Cooperative, where multiple co-locating businesses occupying 13 acres at the Jefferson Airport engage in industrial symbiosis. On the other end of the airport, down by Four Corners, there are 21 acres for a potential industrial park, similar to what was seen on the tour in Denmark.

One lot could have 11 one-acre pads. Under the current code, each could have a 10,000-square-foot building.

“That's where there's the potential to do something a little more direct, like with physical connectivity between buildings,” Berg explained. “We have a couple challenges there. One is, we don't have all of the funding needed to build that infrastructure. And two, there's a need for a variety of different sizes of space. Some of the manufacturers need more than 10,000 square feet. So as we imagine folks growing into larger facilities where they can hire more employees and not leave the county, we may have to address that concern through county zoning. In this context, I do think the larger size facilities probably provide more opportunities for that shared resource.”

An industrial symbiosis lens would suggest they are looking for tenants who naturally make sense to co-locate. The first on the Port’s list of potential renters would be Jefferson County businesses that are outgrowing their space —existing businesses that are trying to hire more people but can't, and are really in jeopardy of leaving our community. Second would be businesses that fit or are aligned with those existing businesses.

One imagining of what this could include the Port Townsend Foundry, a business that reprocesses used materials to make marine hardware, stock metal, and custom castings for industry, municipalities, art, and building. In theory, a garbage incinerator could power it, and businesses that were dependent on a foundry could be nearby, like a CNC metal shop, or somebody assembling or painting parts made at a foundry or cut in a CNC plant.

While climate responsibility is a top priority for the Port, its mission belongs to the working people.

“When you talk about time, I am worried that our current economic conditions are outstripping the ability for the jobs to keep up with our own marketplace, and it is really hard to imagine a Port Townsend that's missing its tradespeople. It feels like it loses an entire dimension of its culture,” Berg said. “So I think that's a force that the Port's really doing everything within its capability to push against by providing more opportunity for the jobs to occur here.”